The House on Main, in Royal Oak, was a great location for my solo show.

In my last post, I discussed the importance of finding a few key people who will make a difference in your journey as an emerging artist. For me, one of these people has been Judy Weiner, owner of House on Main, in Royal Oak, Michigan.

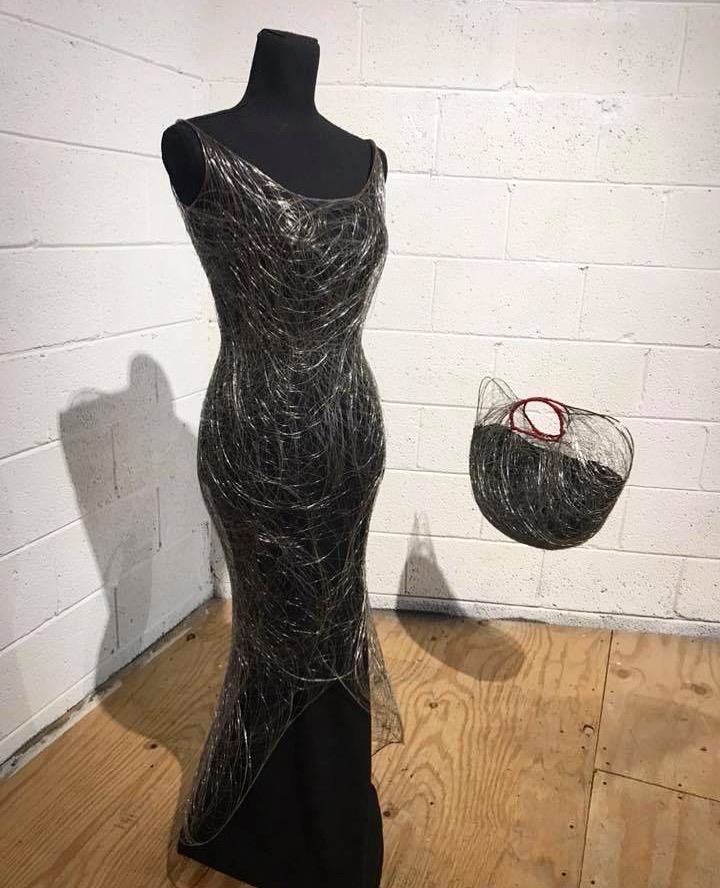

Judy was interested in buying a few of my decor pieces to sell in her clothing and jewelry boutique. A few days later I showed up with a black wire bowl containing three colorful balls. Dressed with impeccable style and an eccentric flair, I could tell right away that Judy was a woman of taste. Not that I understand women’s fashion (or men’s fashion, for that matter), but let’s just say I could tell we would get along.

Judy Weiner in her boutique, the House on Main.

As I got ready to leave I was already thinking about how I’d word the Instagram post; “I just got my stuff in another store! #kickass.” That’s when Judy extended an unexpected offer. She wanted to clear out a large part of the store to make room for my own solo art show. Sure, it may not have been a designated “gallery,” but any space becomes a gallery if you just have some art, and an opening night with wine. I’d be free to choose the date, and we could leave the exhibition up for two weeks (now extended to three). I was at once ecstatic about the offer, while a little bit hesitant to take her up on it. It had been a year since my Annex Gallery opening, and I had new work to show, but my plate was/is already stacked with other projects. While this show would be much smaller, I just wasn’t sure I had the energy for it.

After thinking it over a couple weeks, I realized I’d be crazy not to seize the opportunity. It’s a hip location with a lot of foot traffic, and pretty close to my house. When Judy floated the possibility of my doing a large, outdoor installation right on the front lawn, that sealed the deal.

By the time June 8 rolled around, I had made about 20 large MIG wire balls and had them powdercoated to withstand the elements. Ten of these would make a pyramid to be placed outside the Dexter Public library, and I would take the others to the House on Main.

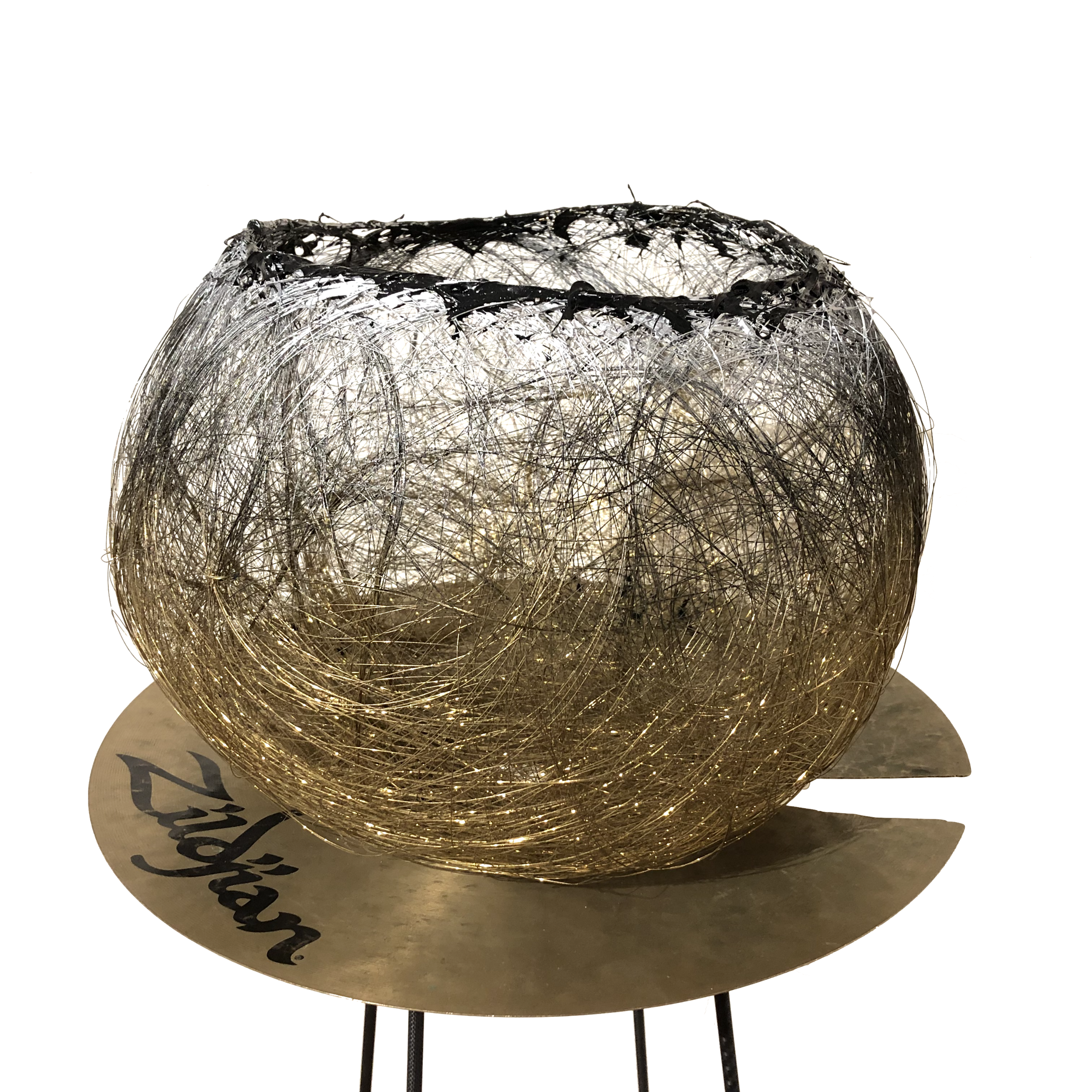

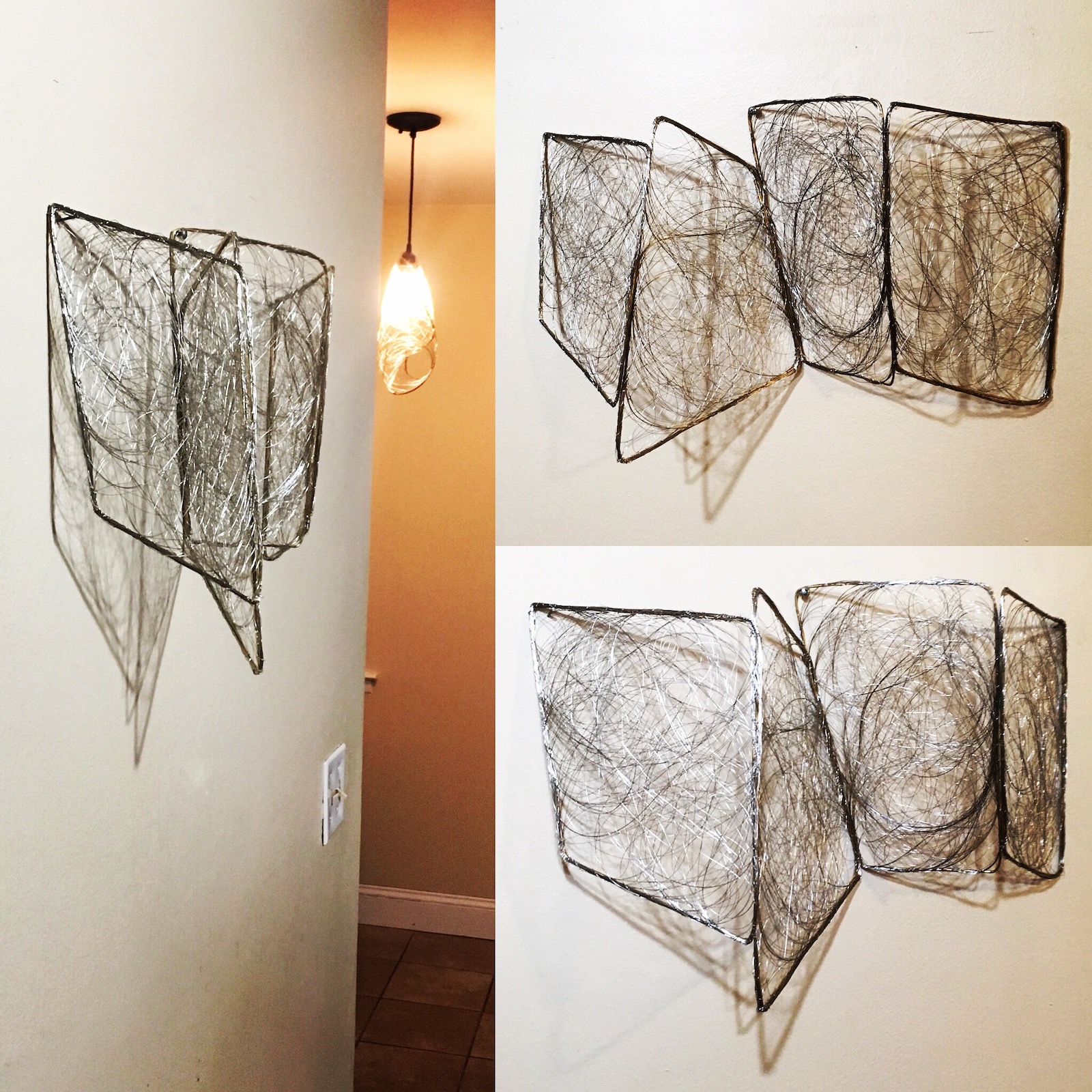

Besides the large outdoor balls, the main pieces I was working on for this show were a series of display stands that would support some wire bowls I had already made. These twelve stands are tripod designs made from carbon fiber and/or aluminum arrows joined in severals different ways, each designed slightly differently. A few feature my old broken drum cymbals, a theme that resurfaces from time to time in my artwork. Some use a brass or aluminum plate, intersected by the arrows. I spent a lot of time on these stands in order to come up with clean looking designs that could support reasonable loads, and could be taken down and reassembled without the use tools or extra hardware. This was not simply for the convenience of whoever might buy them. I wanted a hassle-free, portable art show setup that required minimal space. The result is something not unlike the wire bowls they support; fragile in appearance but reasonably durable and versatile. Arrow sections of various lengths can be swapped out (or cut down) to achieve a desired height. Threaded field points (archery term) are screwed into the bottom pieces so the stands can be pushed down into the grass at outdoor art shows. Who wants to lug around bulky pedestals or heavy display stands? Now, I can fit everything I need (besides the art itself and my tent) into a bag or tube that ends up weighing mere ounces, not pounds. Talk about efficient!

The opening at the House on Main went great, and I sold a bowl/stand combo. I noticed that the stand itself was not sitting level, and at first I thought that was due to the old, uneven floor, but upon further inspection I realized that one of the tripod legs was shorter than the other two. I took the stand home and made a few adjustments to make everything square, and touched up the arrows and center brass piece with steel wool just to make sure the customer was 100% satisfied when he picked it up.

Big thanks to everyone who came to the opening, and especially to Judy, for giving me the opportunity to show my work in a great space!